Cannabinoid Manufacturing Expertise

A breadth and depth of cannabinoid manufacturing methods - all under one roof

InMed and BayMedica have joined forces to bring together cannabinoid manufacturing expertise like no other. We produce rare cannabinoids using a variety of manufacturing techniques including biosynthesis, chemical synthesis and our integrated approach, IntegraSyn™. With multiple cannabinoid manufacturing approaches, InMed has complete flexibility to select the most cost-effective method to deliver a high quality, pure rare cannabinoid fit for its intended use.

No 'one-size-fits-all' approach - selecting the best manufacturing method

When it comes to cannabinoid manufacturing, there is no one size fits all approach. A number of factors such as the complexity of the cannabinoid, its intended use and the quantity needed must be considered before determining which type of manufacturing method to select.

Our capabilities include a selection of cannabinoid manufacturing methods, allowing us to select the best method for each unique cannabinoid and its intended use – ensuring you have a high quality, GMP or lab-certified rare cannabinoid for your products.

Together, we have access to InMed’s IntegraSyn™ and BayMedica’s biosynthesis and chemical synthesis.

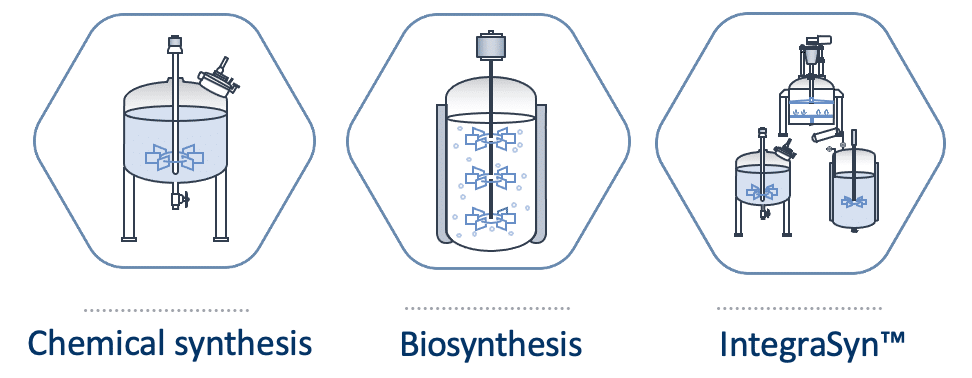

- IntegraSyn™ is InMed’s unique approach to cannabinoid manufacturing. InMed has created genetically engineered microbes that produce proprietary enzymes, which are then used to optimize subsequent biotransformation reactions.

- Biosynthesis entails genetically engineering a microbe, such as bacteria or yeast, to become the living factories to produce the molecules.

- Chemical synthesis involves the combination of starting materials / reactants to produce the selected cannabinoid molecule via a chemical reaction(s).

Each cannabinoid has unique properties and their minor structural differences can have a bearing on which manufacturing method is most efficient. In addition, depending on the intended use of the specific cannabinoid, the required standard of quality will be different. There are different Good Manufacturing Practice (GMP) requirements based on product type.

IntegraSyn™ – a flexible, modular approach to producing cost effective pharmaceutical-grade cannabinoids

IntegraSyn™ is InMed’s integrated cannabinoid synthesis system designed to efficiently and economically produce pharmaceutical-grade bio-identical cannabinoids. The scalable and flexible IntegraSyn™ manufacturing approach integrates multiple commercially proven pharmaceutical methods to efficiently produce cannabinoids, utilizing cost-effective processes. IntegraSyn™ is designed to produce the consistent, compliant, highly pure cannabinoids required for pharmaceutical products.

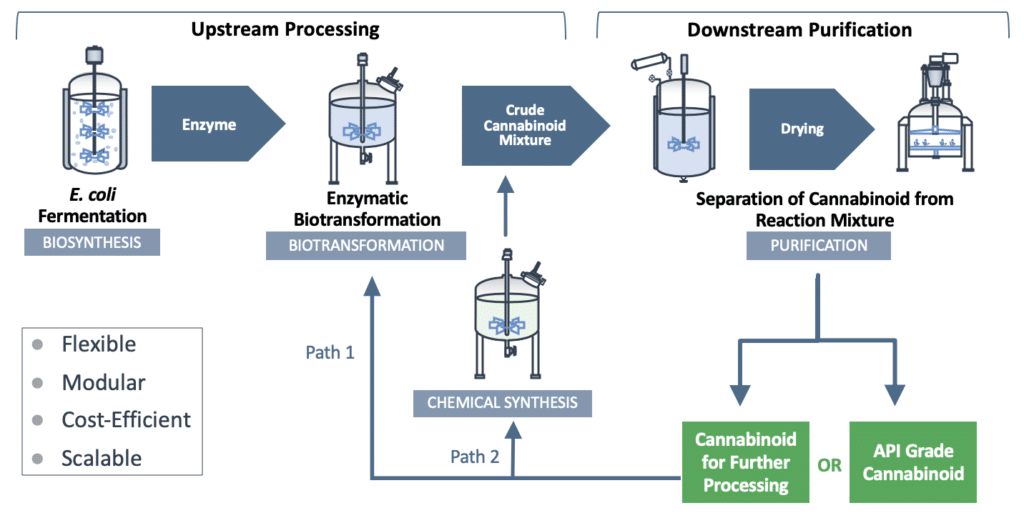

The BayMedica Platform – A biological factory

InMed’s division, BayMedica, has created an efficient, patent-pending, biosynthesis process by transforming common brewer’s yeast into a biological factory. BayMedica utilizes its expertise in synthetic chemistry to complement its biosynthesis platform. BayMedica’s platform has demonstrated that at scale its cannabinoids have both quality and cost advantages over cannabinoids produced via legacy agriculture.

Alternative methods needed to access rare cannabinoids

Each cannabinoid has a specific chemical structure that confers unique physiological effects in humans. Evidence demonstrates that even slight differences in the structure of these compounds can result in profound differences in biological activity, safety and potential therapeutic effect in the human body.

With the natural abundance of tetrahydrocannabinol (THC) and cannabidiol (CBD) in the Cannabis plant, extraction and purification of these cannabinoid(s) is the most common and practical method of production. Rare cannabinoids have been shown to have promising medicinal advantages over the major cannabinoids, but they make up less than 1% of the plant and are expensive and impractical to extract.

Manufacturing rare cannabinoids synthetically – through different lab-certified methods – can provide a cost-effective and environmentally sustainable alternative to the traditional “plant-grow-harvest-extract” technique. Synthesized cannabinoids can also provide the quality, purity and consistency needed for pharmaceutical and consumer products.